MYO JOHNSON SU COMPOST BIOREACTOR

A NO TURN SYSTEM FOR CREATING BIOLOGICALLY DIVERSE, FUNGAL-DOMINATED COMPOST.

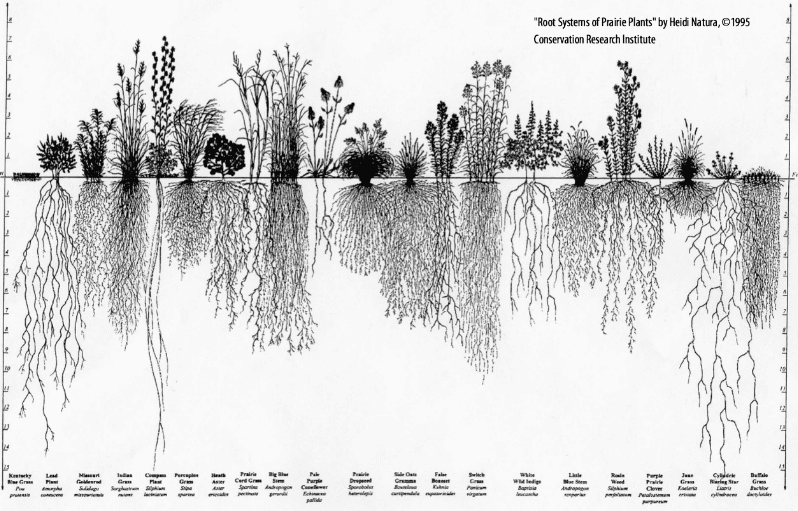

As ecosystems increase in their productivity from bare soil to forests, the balance changes from a bacterial-dominant to a fungal-dominant system, as well as going from low to high carbon content in soils. In his research looking at biological soil enhancements, Dr David Johnson from the Institute of Sustainable Agriculture at New Mexico State University (NMSU), found a high population of soil fungi in the soil is critical to a plant’s productivity in healthy agricultural systems.

The weeds that typically grow well in poor soil are indicative of a low fungal contingent, and play a part in the initial stages of transition from a poorer soil towards one that can support higher order plants. In order to move up the ladder some controlled disturbance is necessary – this can be created by grazing animals, which with their activity and dung, create a microbiological inoculation event that moves with the animals. In the absence of animals or to increase the impact of those animals, the addition to soils of a fungal-dominant and biologically diverse compost inoculant, in combination with a diverse array of living plant roots, will kick start the process of soil transition.

The Johnson-Su Bioreactor & Composting System, developed by Dr Johnson and his wife Hui-Chun Su Johnson, is a method of creating this fungal-rich compost. The bioreactor mimics what happens to dung and organic matter on grasslands,

“it’s approximately 70% moisture content, doesn’t require turning, shouldn’t freeze and is always aerobic.”

Built using easily sourced, relatively cheap materials , it’s placed on a pallet to allow good airflow from below, keeping the process aerobic, together with the six air columns created with pipes during the construction and filling phase. The pipes are pulled out after 24 hours as the pile completely stabilises itself with newly developed fungal hyphae and actinomycetes.

To understand more fully why and how the Johnson-Su Bioreactor & Composting System differs from others watch our webinar or listen to our podcast with the Johnson Su’s:

In this episode of Talkin’ After Hours Jo & Kate chatted to molecular biologist, Dr David Johnson & his wife Hui-Chun Su Johnson about David’s research and development of an agricultural management method called BEAM (Biologically Enhanced Agricultural Management) and the now renowned composting system he devised with Hui-Chun called the Johnson-Su Compost Bioreactor.

Additional Resources:

Making a JS Bioreactor Using IBC’s

You need 1.5 IBC’s per bioreactor. One cage is made into two small base cages. The design makes it easier to get the material out when mature by taking off the top cage and then it is easier to shovel out the finished compost. Each one makes about 250kg of finished product. (ie. enough to foliar spray 250 hectares of plants)

Responses